“Manufacturing builds the future,” says Gerald Johnson, GM executive vice president of Manufacturing and Sustainability.

In 2021, that statement was clearly demonstrated as our employees continued to show tremendous fortitude in the face of adversity with global COVID-19 challenges and supply chain shortages. Our team forged on and found new ways to keep GM moving forward, innovating and building toward the future.

From corporate announcements to production launches, to plant anniversaries and investments, GM and our manufacturing facilities had much to celebrate in 2021.

January

GM started the year strong by introducing the world to our new logo and corporate rally cry “Everybody In” to reinforce our comprehensive efforts to accelerate the mass adoption of electric vehicles.

February

- Assembled at Orion Assembly1, Chevrolet expanded its electric vehicle portfolio with the new, all-electric 2022 Bolt EUV, alongside the redesigned 2022 Bolt EV.

- To support full-size truck production, we announced a $75 million investment in Toledo Transmission to help increase the plant’s capacity to build 10-speed automatic transmissions for full-size trucks like the Chevrolet Silverado and GMC Sierra.

- We announced a $100 million investment in two manufacturing facilities, $93 million at Romulus Powertrain in Michigan and $7 million at Bedford Casting Operations in Indiana to boost full-size truck transmission capacity.

April

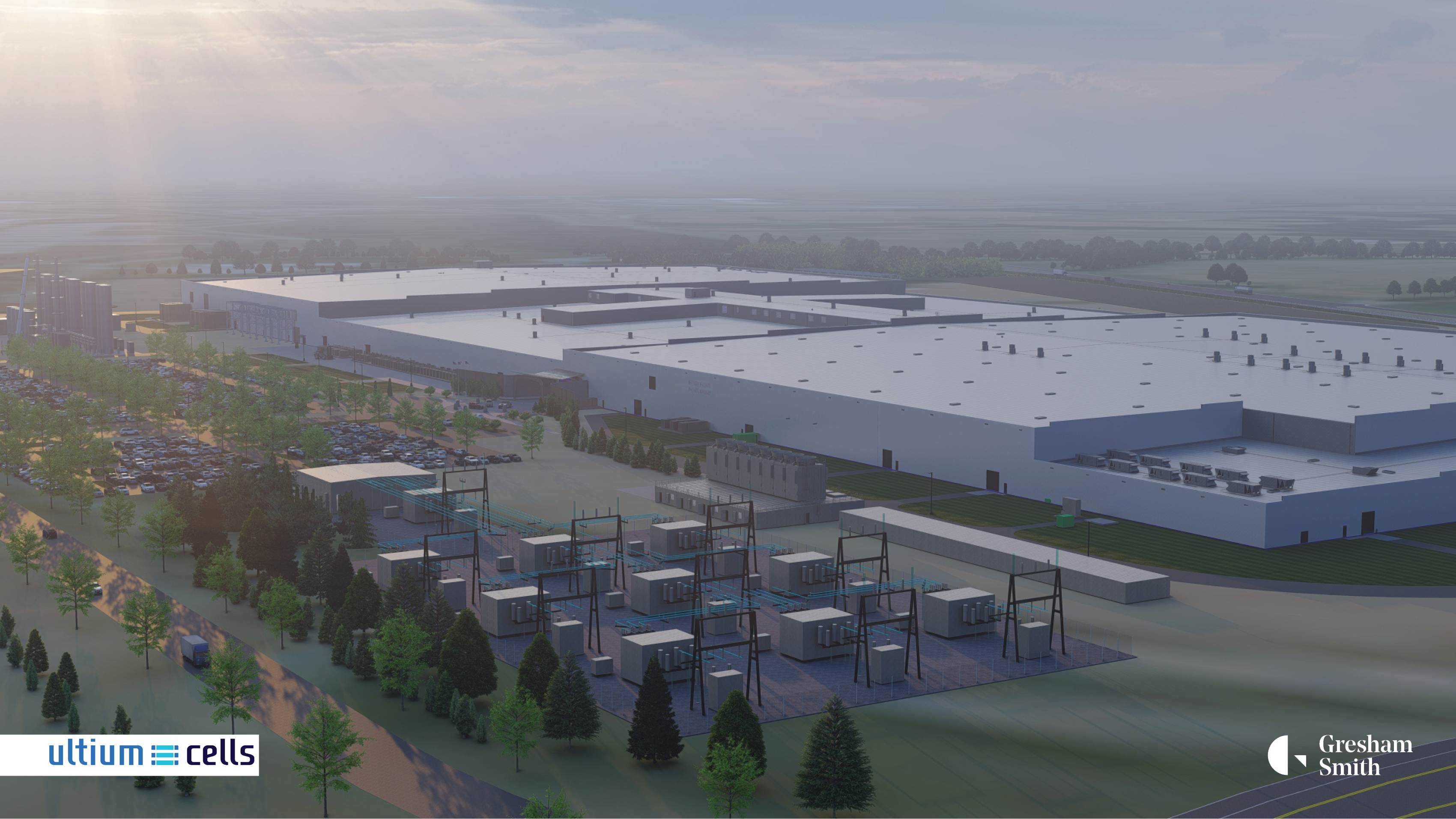

In April, we announced plans to invest $2.3 billion in a second Ultium Cells LLC facility in Spring Hill, Tennessee, to support our expanding roster of EVs. Scheduled to open in late 2023, the facility will supply battery cells to Spring Hill Manufacturing.

May

- Grand Rapids Operations celebrated its one millionth axle. This landmark achievement arrived nearly three years to the day from when the plant began axle production.

- Lansing Delta Township (LDT) Assembly celebrated its 15th anniversary this year. First assembling the Saturn Outlook in 2006, LDT now delivers high-quality Chevrolet Traverse and Buick Enclave SUVs. We are proud of what LDT continues to accomplish as we work towards building a safer world through our vehicles.

- We announced plans to invest $40 million in our Pontiac Metal Center. The investment will help renovate the existing facility and install new equipment to support future electric vehicle production and various product applications.

June

- Bowling Green Assembly (BGA) in Kentucky is the only plant in the world to build the iconic Chevrolet Corvette and the plant celebrated its 40th anniversary this year.

- Announced an increase in EV and AV investments from 2020 through 2025 to $35 billion to help accelerate our transformative strategy to become the market leader in EVs in North America.

- At an event later in the year, families were invited to come take photos with different Corvette models assembled at BGA over the years.

- In 2019, the Chevrolet Suburban became the first vehicle to earn an Award of Excellence star from the Hollywood Chamber of Commerce for its iconic role in film and television. This past June, leaders unveiled the star’s permanent location in Texas in the Arlington Entertainment District. The Suburban is proudly built in Texas at our Arlington Assembly plant.

- Our success in the retail market for full-size SUVs and pickups is a testament to our employees who make only the best. At Arlington Assembly, the team assembled the 12th million vehicle in the facility’s history this year, and we can’t wait for 12 million more!

July

- In 1911, the Chevrolet Motor Company was launched and in 2021, the iconic brand celebrated its 110th anniversary. Chevrolet is one of the world’s largest car brands with more than 3.2 million cars and trucks sold in 2020 in 79 countries.

- Before our groundbreaking new autonomous vehicle - the Cruise Origin - can roll off the assembly line and onto the street, our processes, technology and performance must be tested. That’s why nearly 100 preproduction Origins were built at GM’s pre-production operations (PPO) site in Warren, Michigan in July. GM’s PPO facilities house roughly 200 salaried and more than 800 hourly employees – almost all of which are skilled trades – who manually assemble vehicles - primarily by hand.

August

The 2022 Cadillac CT5-V Blackwing and CT4-V Blackwing launched at Lansing Grand River Assembly. As the fastest-ever sport sedans, they represent the pinnacle of Cadillac performance and craftsmanship.

September

Our great team at Flint Assembly celebrated the 15 millionth heavy duty truck coming off the line. We continue to make some of the best, most popular heavy-duty trucks in the world and we thank our employees who have been doing it for decades!

October

- The all-new Chevrolet Corvette Z06 reveal was a total team effort and a testament to all Bowling Green Assembly employees.

- Revealed by the tag “Putting the world on notice,” we hope everyone notices the tremendous work that went into the vehicle by our team!

- Our Marion Metal Center in Indiana celebrated its 65th anniversary and highlighted people – past and present. Videos, photos, leader recognitions from GM and the UAW, historic vehicles with parts stamped at Marion and a delicious BBQ lunch made for a festive event. Each employee was given a commemorative stamped coin in recognition of the part they play at Marion.

- Production of the 2022 Chevy Traverse and Buick Enclave at LDT began. All areas of the organization, from Engineering to Manufacturing, Material and Quality worked hard to design, prepare and train our team for the new models.

November

- We pulled out all the stops for the grand opening of Factory ZERO, including hosting President Joe Biden, International UAW and UAW Local 22 leadership, plant employees and other officials in celebration of this major milestone in GM’s history. The EVs assembled at Factory ZERO will transform the automotive industry and will be home to the 2022 GMC HUMMER EV Pickup, 2024 GMC HUMMER EV SUV, Chevrolet Silverado EV and the Cruise Origin, an all-electric, self-driving, shared vehicle.

- Our Lansing Grand River assembly facility celebrated 20 years in the community. In 2001, Lansing Grand River began production of its first product, the 2003 Cadillac CTS.

- Supporting both current product and future vehicle programs, GM announced a $46 million investment at Parma Metal Center.

December

We announced plans to invest more than $51 million to install state-of-the-art equipment at our Bedford, Indiana aluminum die casting foundry to support the manufacture of drive unit castings for the upcoming Chevrolet Silverado EV and other current casting applications. The 1 million square-foot site also produces electric drive unit castings for the 2022 GMC HUMMER EV Pickup and the upcoming 2024 GMC HUMMER EV SUV.

- From globally sourced parts.